1. Biomass Storage

2. Biomass Conveyor

3. Biomass Buffer Bin

4. Biomass Gasifier

5. Cyclone Dust Collector

6. Gas Filter

7. ESP

8. Gas Scrubber

9. Gas Dryer

10. Blower

11. Buffer Tank

12. Gas Flare

13 Gas Generator Sets

Office Address:4th floor, Chuangrong Building Block C, Danshan Road, AnzhenStreet, Xishan District, Wuxi, Jiangsu, China.

Factory Address:No.26 Jingrui Rd, Xibei Town, Xishan District, Wuxi, Jiangsu, China.

Skype: tnjd168

Email:info@powermaxgasifiers.com

Email:sales@powermaxgasifiers.com

Mobile/WhatsApp: +86-13812083566

Tel:+86-510-68229610

POWERMAX RICE HUSK GASIFICATION POWER PLANT

The basic principle of POWERMAX’s rice

husk biomass gasification power generation system(abbreviated as BGPS)

is to convert rice husk,rice hull into combustible gas . It is then used

as fuel in gas engine to generate electricity. Biomass gasification

successfully conquers the disadvantages of rice husk biomass, such as

low flammability and wide diversity. Biomass gasification system is

characteristic of small land requirement and environment friendly. It’s

one of the most effective way of biomass utilization.

Necessary Requirement of Rice husk can be used in POWERMAX Rice Husk Gasification Power Plant:

Humdity of rice husk less than 20%.

POWERMAX RICE HUSK GASIFICATION POWER PLANT PROCESS

Our biomass(rice husk) gasification

process includes three steps. The First step is biomass gasification,

which convert rice husk into syngas. The Second step is syngas

purification. The producer gas coming from gasifier usually contains

contaminants including dust, coke, tar and etc. The contaminants will be

removed by the purification system to ensure normal operation of gas

engine. The Third step is power generating in gas engine. The high

temperature exhaust gas may be reused by waste heat boiler to generate

steam or hot water for civil or industrial use). Steam turbine may also

be considered to make a gas-steam combined cycle power plant, which will

increase the total efficiency.

Technology Of POWERMAX Rice Husk Gasification Power Plant

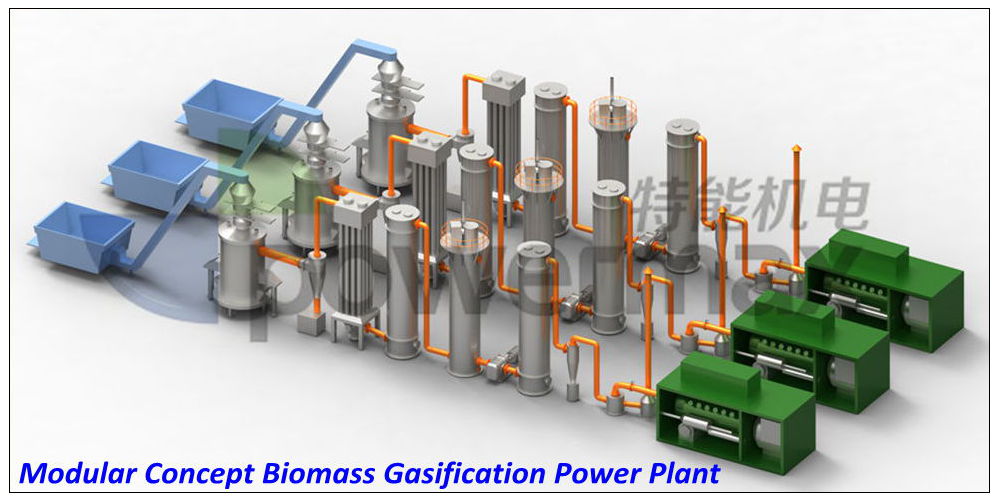

The POWERMAX rice husk gasification power

generation systems are based on a modular concept and are able to

applicable for 50-20000KW rice husk biomass power station. There are two

series of biomass gasification system designed for rice husk by

POWERMAX which ranges from 50-2000KW of power generation: CFBG

(Circulating Fluidized Bed Gasifier) Series, DFBG(Downdraft Fixed Bed

Gasifier) Series A series biomass generator sets from 50KW to 1000KW are

developed by POWERMAX to combine with POWERMAX advanced gasification

technology. These gas generator sets are using the high efficiency

Siemens technology alternators, Chinese top brand medium speed gas

engine(500-1000rpm),German Detuz Gas Engine(1500rpm) with advanced

European engine control systems. The high performance of the POWERMAX

biomass gasification plants and the later production of electricity with

the gensets represents a competitive solution when compared with

conventional boiler-fired system.

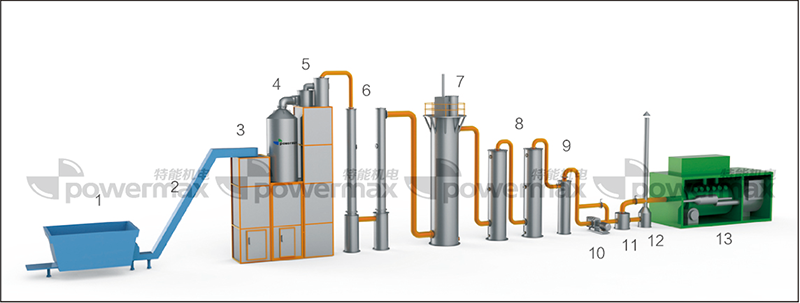

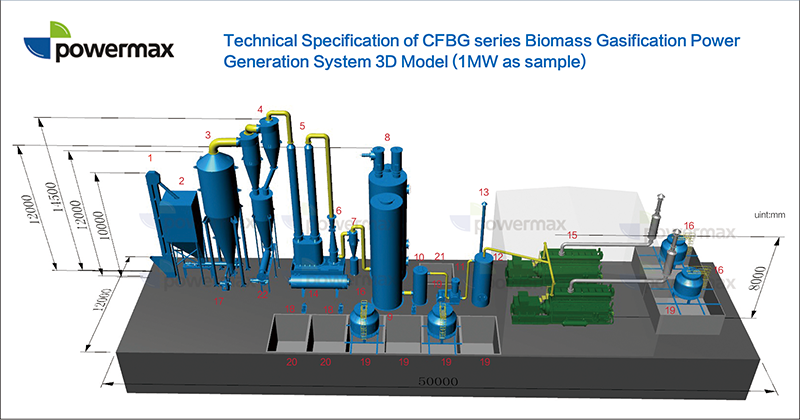

Powermax CFBG Power Plant

Our CFBG system can directly to use rice husk !!!

1. Biomass Storage

2. Biomass Conveyor

3. Biomass Buffer Bin

4. Biomass Gasifier

5. Cyclone Dust Collector

6. Gas Filter

7. ESP

8. Gas Scrubber

9. Gas Dryer

10. Blower

11. Buffer Tank

12. Gas Flare

13 Gas Generator Sets

Technical Specification of CFBG series Biomass Gasification Power Generation System

| Model | 200CFBG | 400CFBG | 500CFBG | 600CFBG | 800CFBG | 1000CFBG | 1200CFBG | 1500CFBG | 2000CFBG |

| Rated Power(kw) | 200 | 400 | 500 | 600 | 800 | 1000 | 1200 | 1500 | 2000 |

| Rated Frequency | 50 /60 HZ | ||||||||

| Rated Voltage(V) | 220 / 400 / 440 / 6300 / 6600 / 11000 /13800 | ||||||||

| Model of Gasifier | CFBG200 | CFBG400 | CFBG500 | CFBG600 | CFBG800 | CFBG1000 | CFBG1200 | CFBG1500 | CFBG2000 |

| Gasifier Type | Circulating Fluidized Bed Gasifier(CFBG) | ||||||||

| Biomass Moisture Requirement | ≤20%(wet basis) | ||||||||

| Biomass Size Requirment | ≤8-15mm | ||||||||

| Biomass Consumption(Kg/hr) | 200-360 | 400-720 | 500-900 | 600-1080 | 800-1440 | 1000-1800 | 1200-2160 | 1500-2700 | 2000-3600 |

| Gas Production(Nm3/h) | 500-600 | 1000-1200 | 1250-1500 | 1500-1800 | 2000-2400 | 2500-3000 | 3000-3600 | 3750-4500 | 5000-6000 |

| Ash Discharge Type | Dry Ash Type | ||||||||

| Type of Gas Purification | POWERMAX Semi Dry Type Gas Purification System | ||||||||

| Heat Value of Gas | 1200-1300Kcal/Nm3 | ||||||||

| Gas Composition | CO-12~18%, CO2-10~16%, CH4-4~8% H2-3~7% CnHm-1~1.4% O2-0.5~1.2% N2-54~60% | ||||||||

| Model of Gensent | 100GFLS | 400GFLS | 500GFLS | 300GFLS | 400GFLS | 1000GFLS | 400GFLS | 500GFLS | 1000GFLS |

| Qty of Genset | 2 | 1 | 1 | 2 | 2 | 1 | 3 | 3 | 2 |

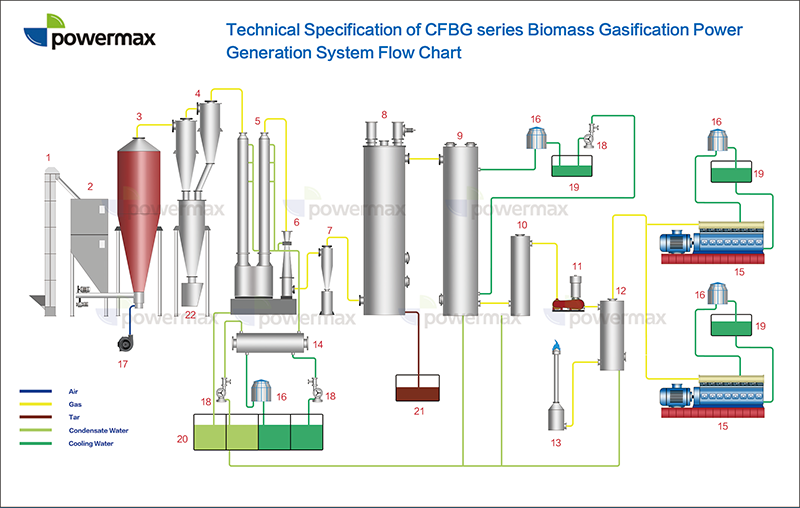

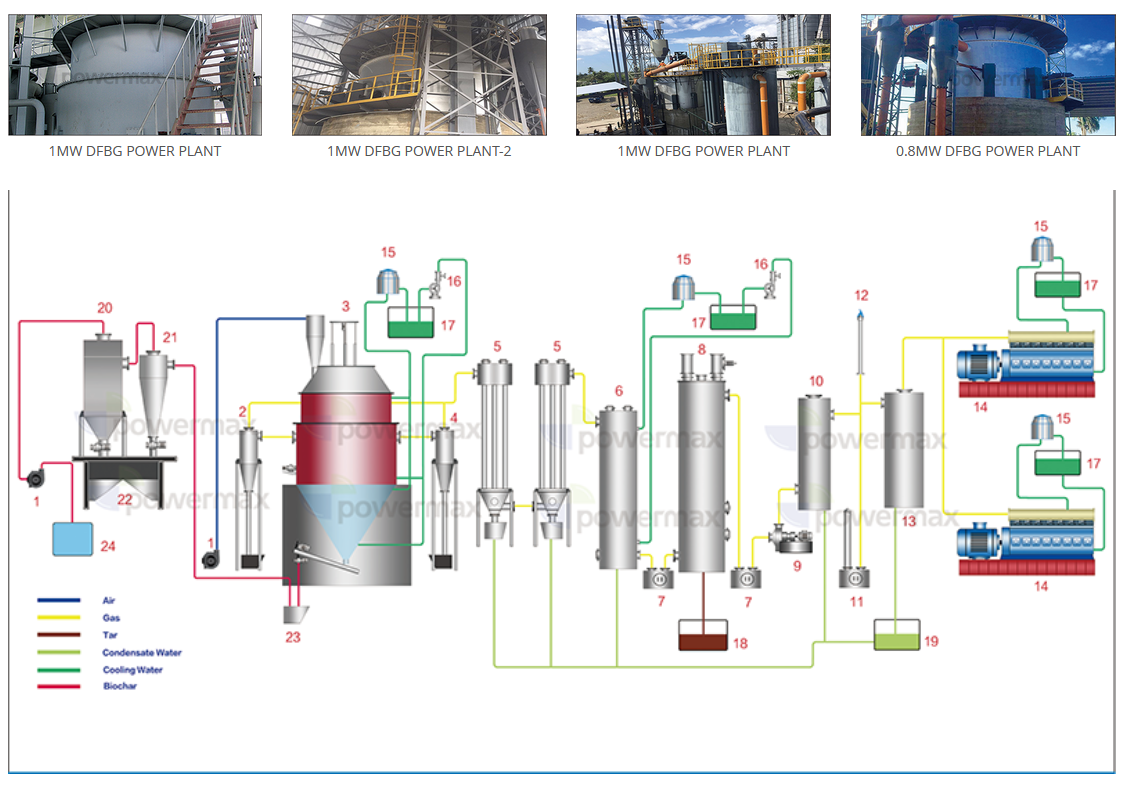

1.Elevator

2.Feed Bin

3.Gasifier

4.Cyclone

5.Tube Type Dust Remover

6.Venturi

7.Cyclone Hydraulic Separators

8.ESP

9.Indirect Cooler

10.Water Drop Catcher

11.Roots Blower

12.Buffer Tank

13.Vent Cans&Gas Flare

14.Tubular Heat Exchanger

15.Gas Generator Set

16.Cooling Tower

17.Air Blower

18.Water Pump

19.Cooling Water Pool

20.Condensate Water Pool

21.Tar Tank

22.Biochar Outlet

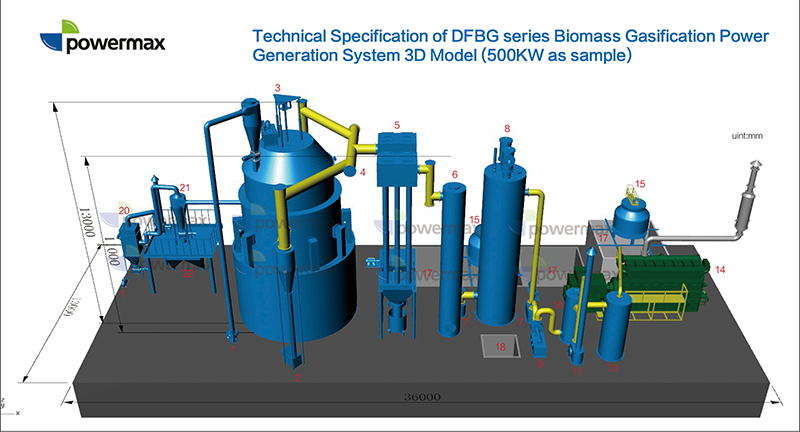

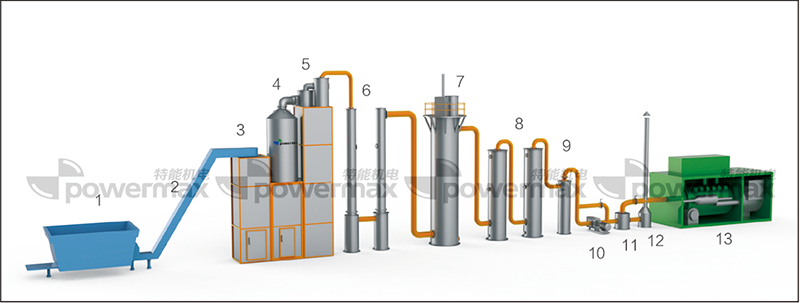

Powermax DFBG Power Plant

Our DFBG system can directly to use rice husk !!

1. Biomass Storage

2. Biomass Conveyor

3. Biomass Gasifier

4. Cyclone Dust Collector

5. Air Cooler

6. Gas Cooler

7. ESP

8. Gas Cooler

9. Gas Dryer

10. Buffer Tank

11. Gas Flare

12. Gas Generator Sets

13. Blower

| Model | 50DFBG | 100DFBG | 200DFBG | 300DFBG | 400DFBG | 500DFBG | 600DFBG | 800DFBG | 1000DFBG |

| Rated Power(kw) | 50 | 100 | 200 | 300 | 400 | 500 | 600 | 800 | 1000 |

| Rated Frequency | 50 /60 HZ | ||||||||

| Rated Voltage(V) | 220 / 400 / 440 / 6300 / 6600 / 11000 /13800 | ||||||||

| Model of Gasifier | DFBG50 | DFBG100 | DFBG200 | DFBG300 | DFBG400 | DFBG500 | DFBG600 | DFBG800 | DFBG1000 |

| Gasifier Type | Downdraft Fixed Bed Gasifier | ||||||||

| Biomass Moisture Requirement | ≤16%(wet basis) | ||||||||

| Biomass Size Requirment | Less than 1cm | ||||||||

| Biomass Consumption(Kg/hr) | 50-100 | 100-200 | 200-400 | 300-600 | 400-800 | 500-1000 | 600-1200 | 800-1600 | 1000-2000 |

| Gas Production(Nm3/h) | 125-150 | 250-300 | 500-600 | 750-900 | 1000-1200 | 1250-1500 | 1500-1800 | 2000-2400 | 2500-3000 |

| Ash Discharge Type | Dry Ash Type | ||||||||

| Type of Gas Purification | Dry Type Gas Purification System | ||||||||

| Heat Value of Gas | ≥1100Kcal/Nm3 | ||||||||

| Gas Composition | CO-15~20%, CO2-8~12%, CH4-upto 4% H2-10~15% N2-45~55% | ||||||||

| Model of Gensent | 50GFLS | 100GFLS | 100GFLS | 300GFLS | 400GFLS | 500GFLS | 300GFLS | 400GFLS | 1000GFLS |

| Qty of Genset | 1 | 1 | 2 | 1 | 1 | 1 | 2 | 2 | 1 |

1.Biomass Fuel Blower

2.Cyclone

3.Gasifier

4.Cyclone

5.Air Cooler

6.Indirect Cooler

7.Isolation Seal

8.ESP

9.Booster Fan

10.Water Drop Catcher

11.Water Bleeding

12.Gas Flare

13.Buffer Tank

14.Gas Generator Set

15.Cooling Tower

16.Water Pump

17.Cooling Water Pool

18. Tar Tank

19.Condensate Water Pool

20.Pulse Dust Collector

21.Cyclone Dust Collector

22.Ash Tank

23.Ash Discharge Transition Hopper

24.Water Tank