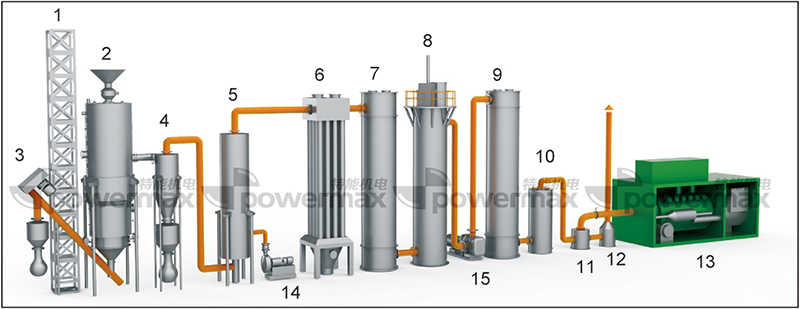

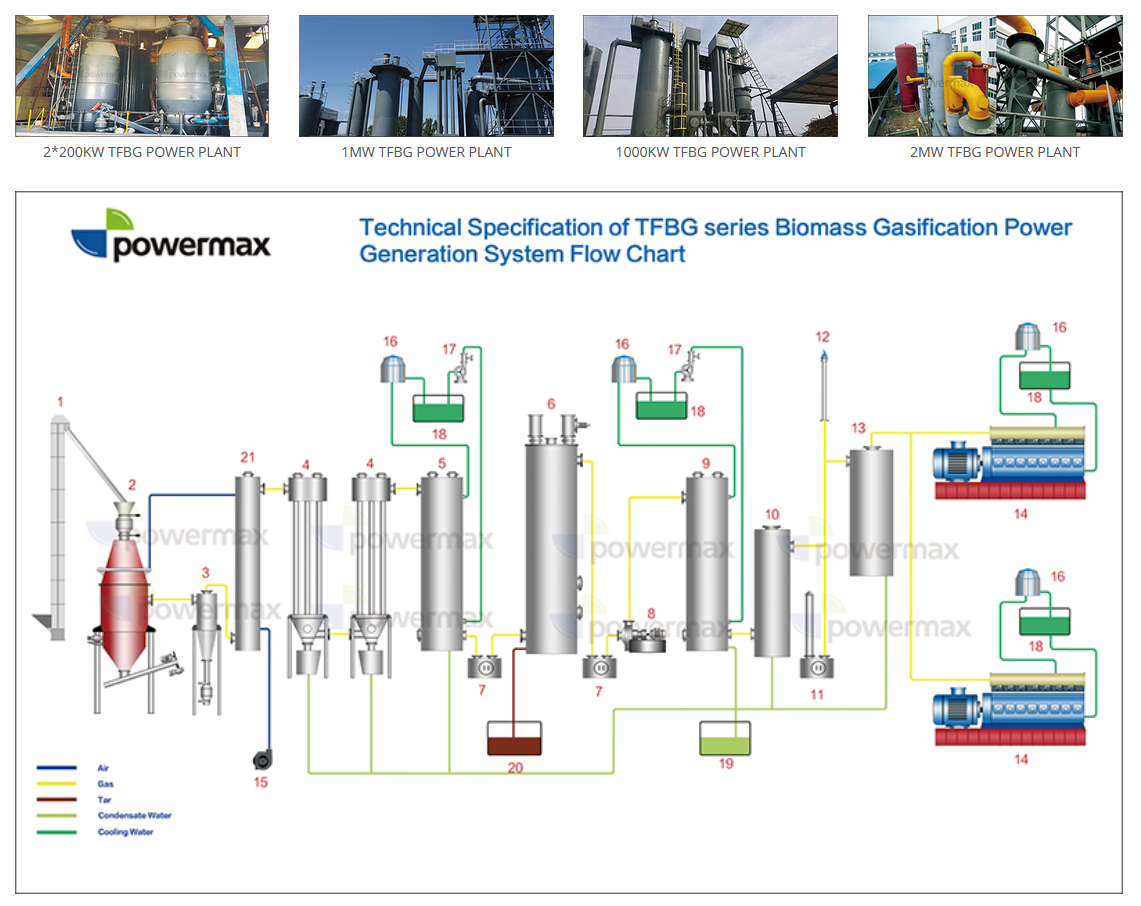

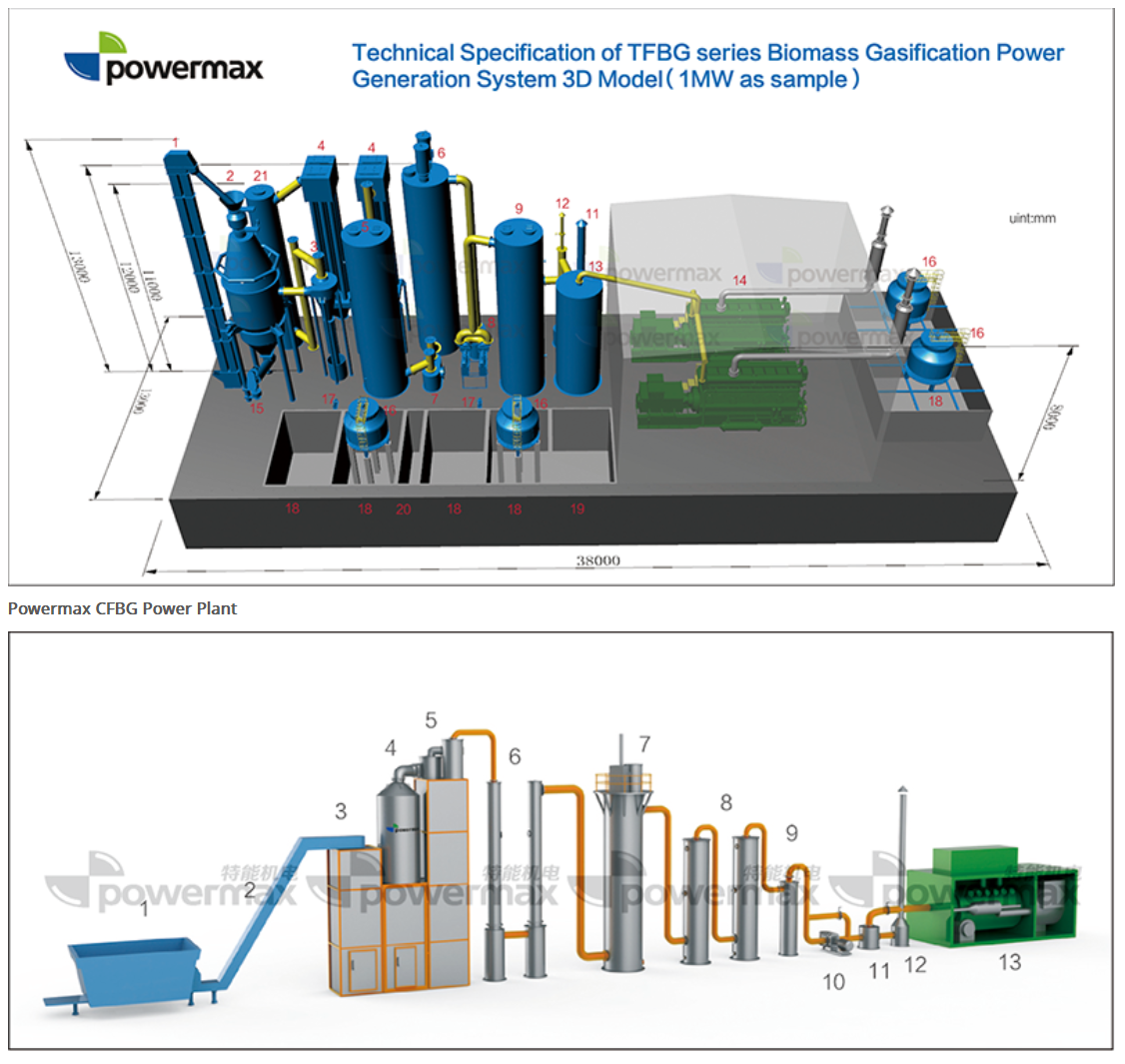

1. Skip Charger

2. Biomass Gasifier

3. Dry Ash Discharger

4. Cyclone Dust Collector

5. Hot Air Heat Exchanger

6. Air Cooler

7. Gas Cooler

8. ESP

9. Gas Cooler

10. Gas Dryer

11. Buffer Tank

12. Gas Flare

13. Gas Generator Sets

14. Blower

15. Gas Compressor

中文

中文 EN

EN

ENGLISH

ENGLISH 简体中文

简体中文