-

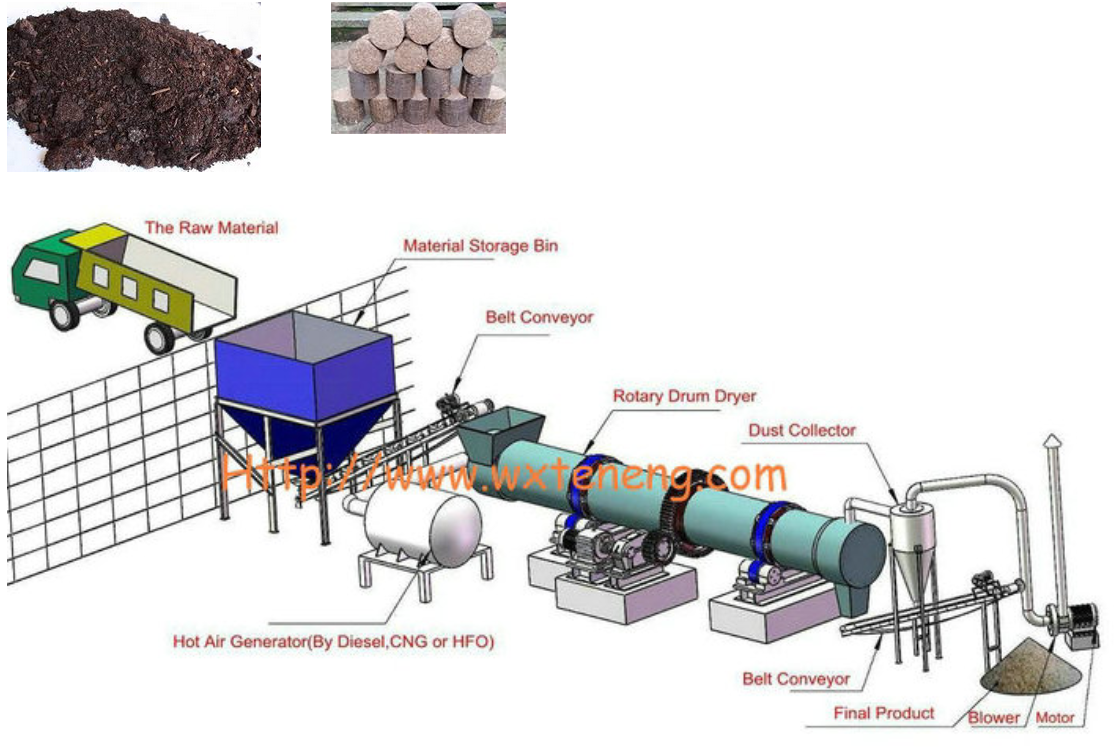

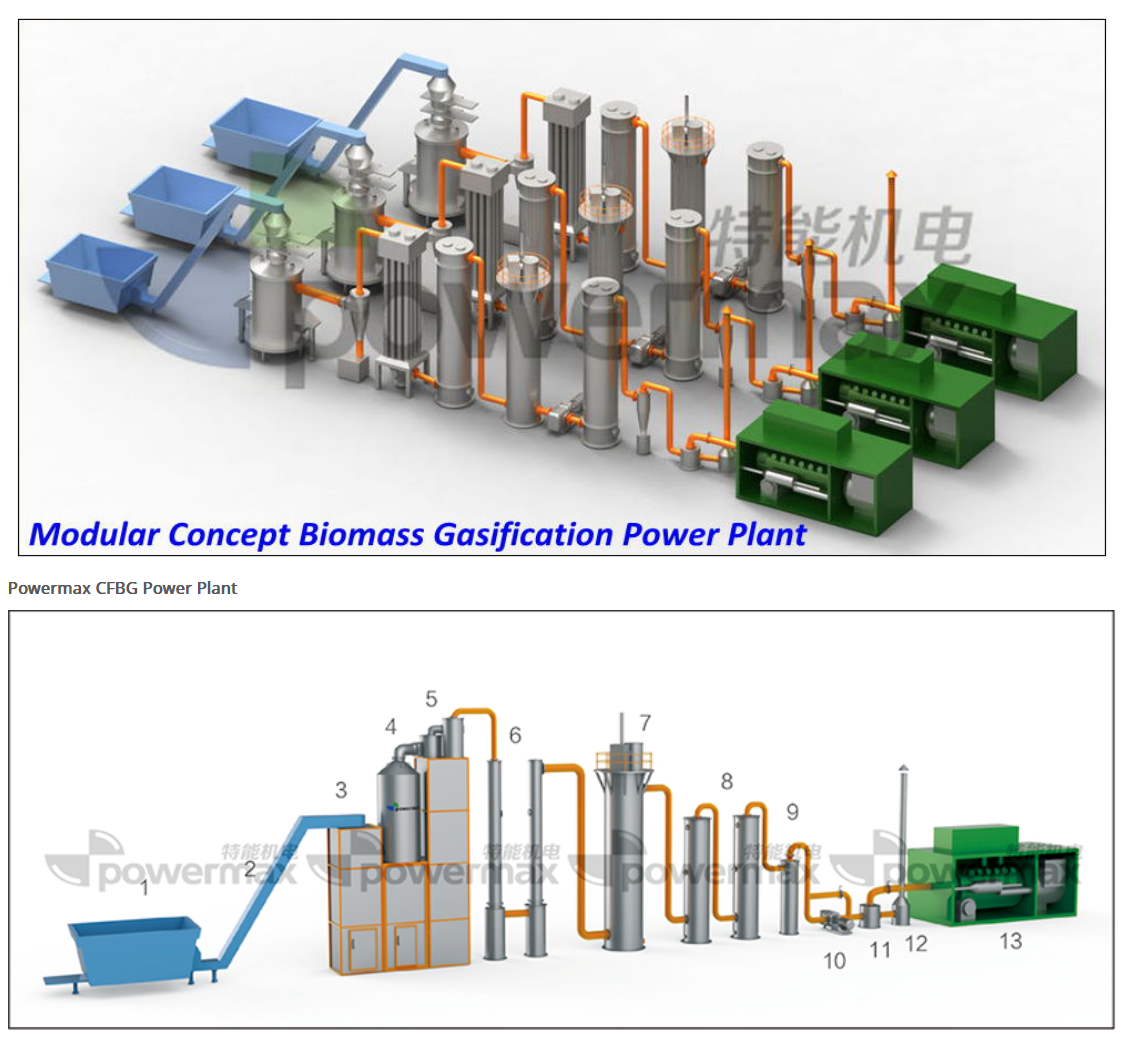

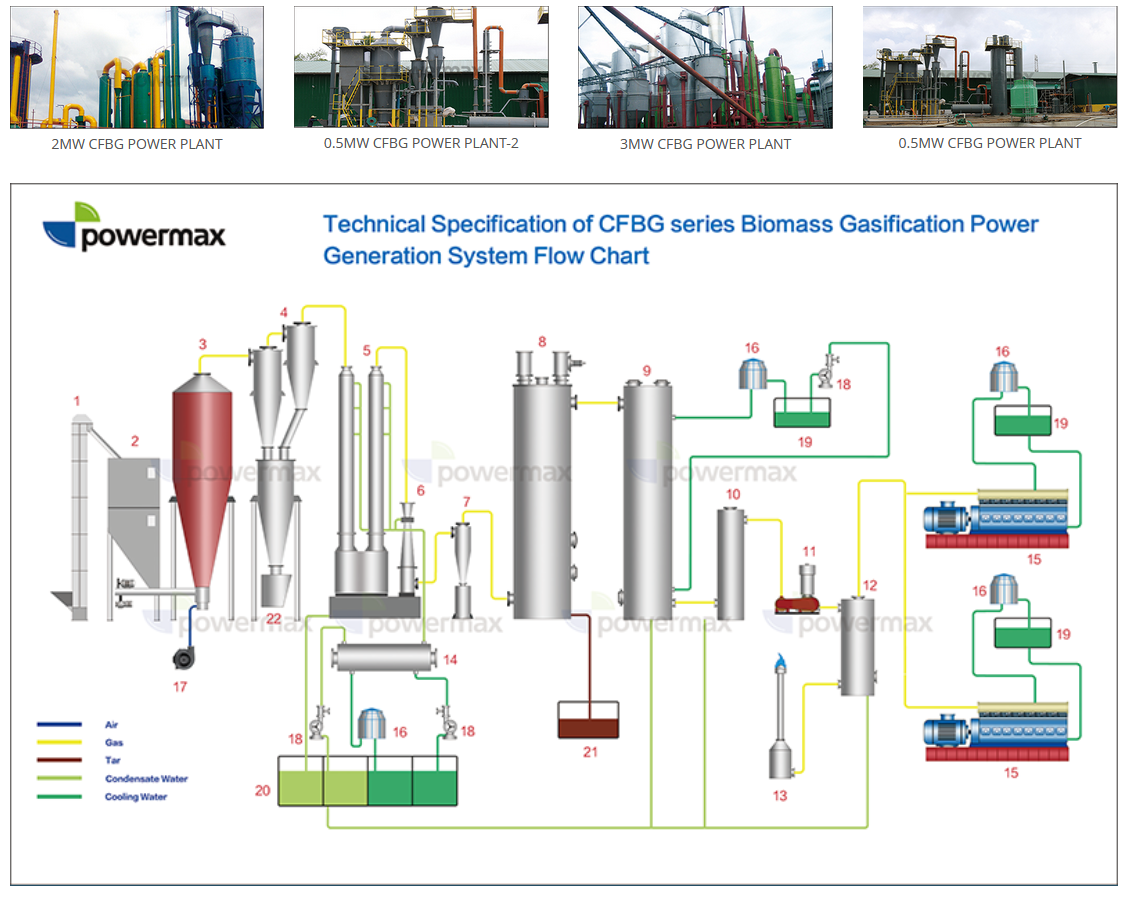

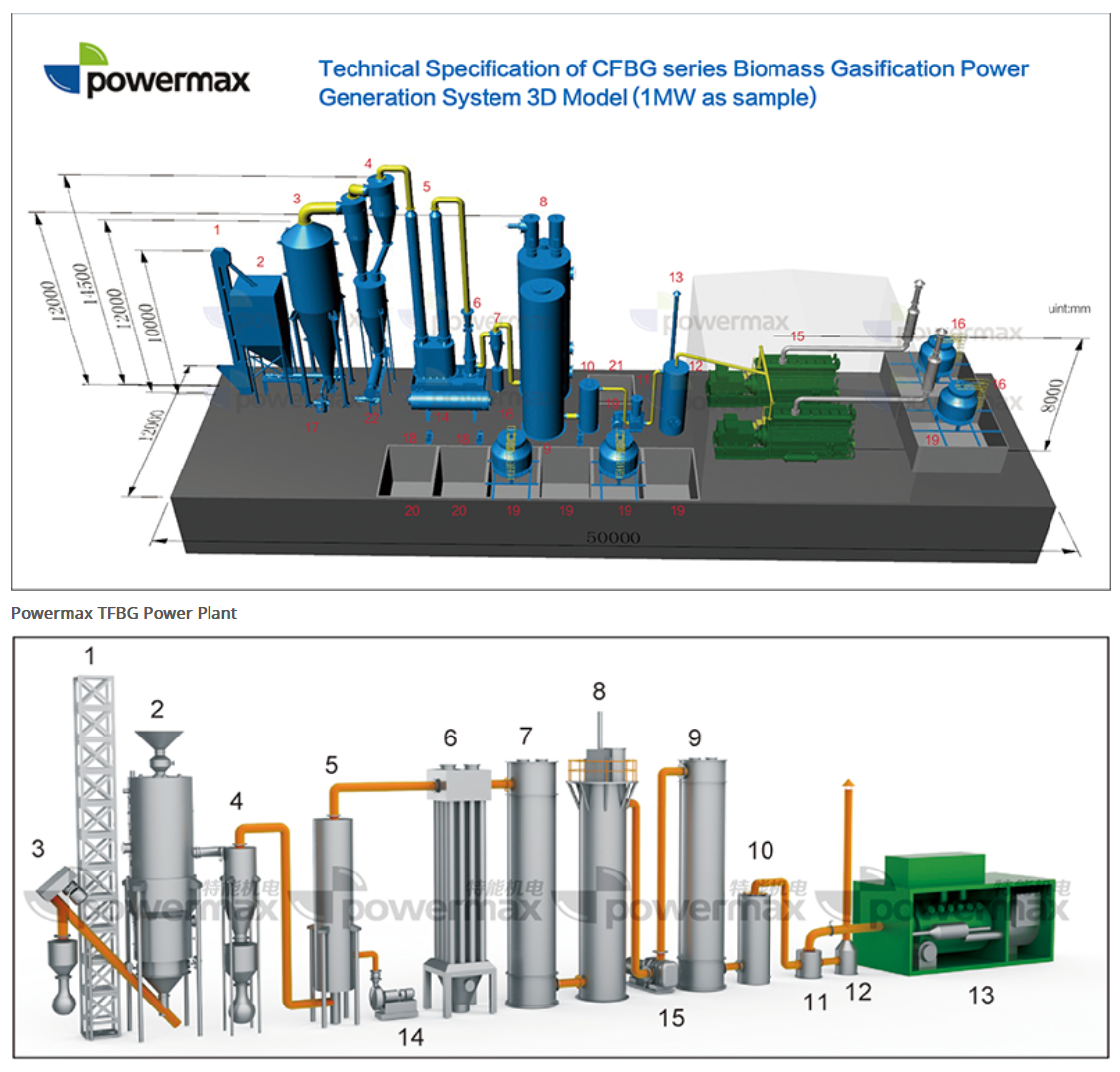

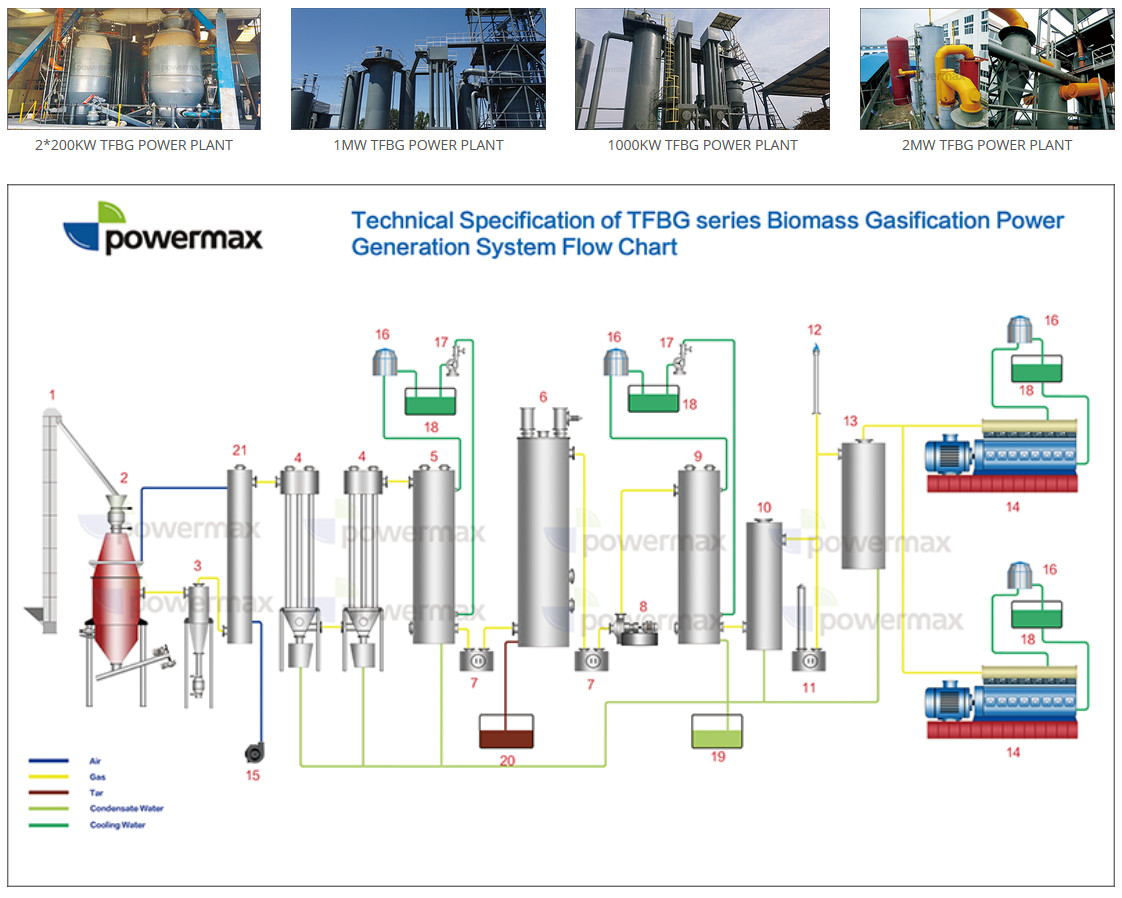

1. Biomass Storage

-

2. Biomass Conveyor

-

3. Biomass Buffer Bin

-

4. Biomass Gasifier

-

5. Cyclone Dust Collector

-

6. Gas Filter

-

7. ESP

-

8. Gas Scrubber

-

9. Gas Dryer

-

10. Blower

-

11. Buffer Tank

-

12. Gas Flare

-

13 Gas Generator Sets

中文

中文 EN

EN

ENGLISH

ENGLISH 简体中文

简体中文