Powermax Biomass Pyrolysis Gasification

Power Generation System

Technical Leader of Chinese Biomass Gasification

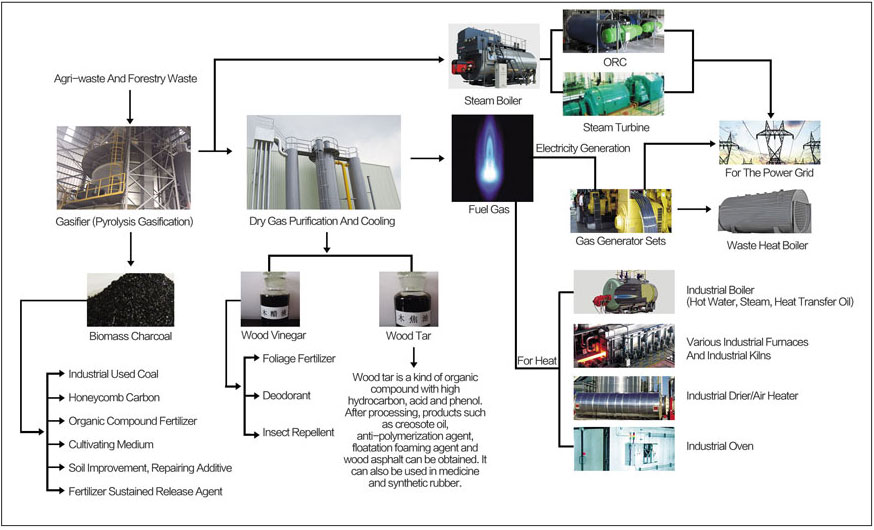

| Biomass Charcoal

|

Wood Tar

|

Wood Vinegar

|

|

Charcoal

can be widely applied in our daily life, like cooking, baking, and

rinsing in catering industry. In agriculture, it can improve the soil

quality, promote the formation of soil aggregates, and regulate the soil

ecosystem. Moreover, it can reduce the extractable metal content of the

soil to promote the growth of crops. In industry, charcoal, coconut

coal, palm shell charcoal are necessary raw materials in the production

of activated carbon, and rice husk charcoal can be widely applied in

smelting industry.

|

Wood

tar is a kind of organic compound with high hydrocarbon, acid and

phenol. After processing, products such as creosote oil,

anti-polymerization agent, floatation foaming agent and wood asphalt can

be obtained. It can also be used in medicine and synthetic rubber.

|

It

is environmental friendly, and it can be applied to medicine original

department (skin disease), food additive (fumigant), fuel original

liquid (coal stain agent raw material), deodorant, pesticide raw

material, etc. |

Technology Introduction

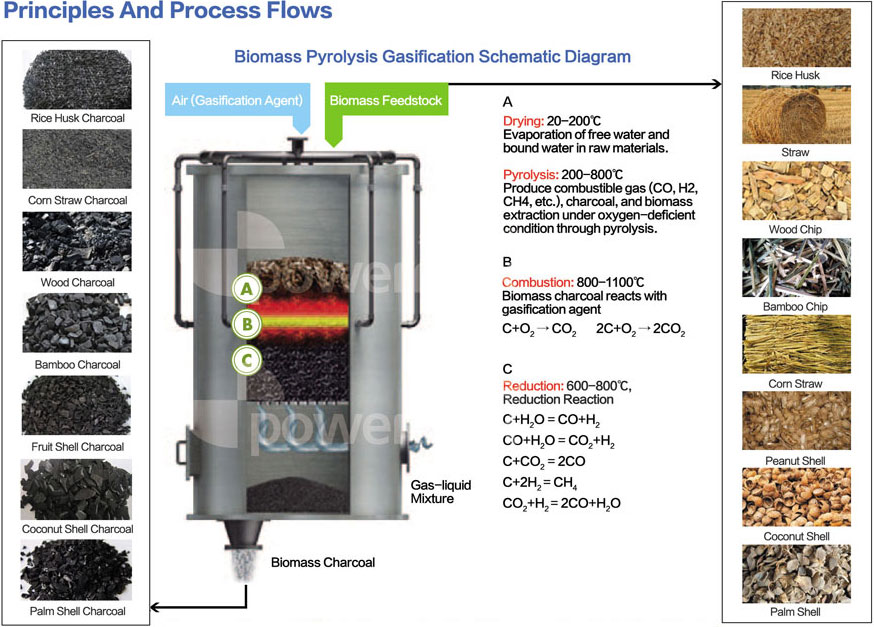

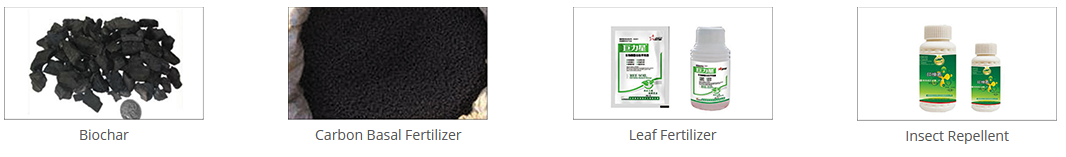

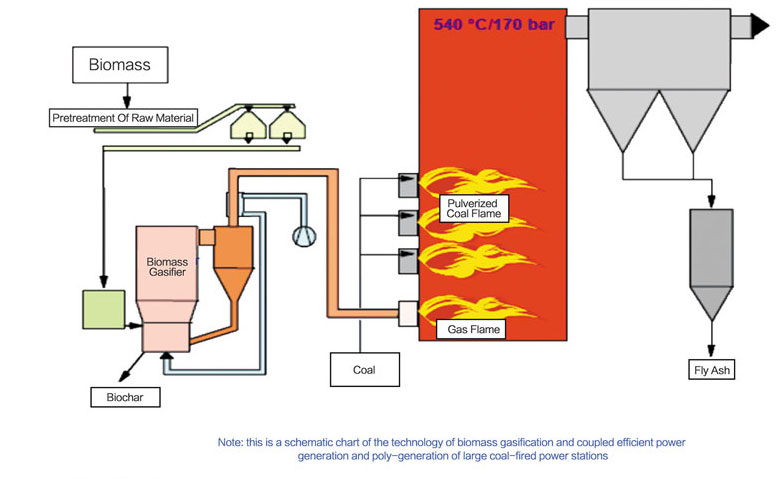

This technology uses

thermochemistry conversion method. With Powermax independent R&D

technology, biomass (rice husk, straw, cotton stalk, corn straw, wood

ships, bamboo and other agriculture and forestry waste) can be converted

into various kinds of products like syn-gas, electric energy, biomass

charcoal, heat energy (steam, hot water), carbon basal fertilizer,

foliage fertilizer. Moreover, the biomass can be turned into wealth and

can be made full use of.

The basic principle of

Powermax biomass gasification power generation system (BGPS) is to

convert the agriculture and forestry products and wood processing

remains such as rice husk, sawdust, branches, forestry waste, straw,

rice straw, wheat straw, rice husk, shell, corn stalk, millet rod,

cotton stem, bagasse, coconut shell, corn cob, corn cob wastes into gas,

and use the combustible gas to drive gas generating equipment for

electricity. It can not only solve the problems that biomass is

difficult for combustion and collection, but also take full advantage of

the equipment’s compact-design and environmental-friendly features.

Therefore, it is one of the most eco-friendly way for biomass.

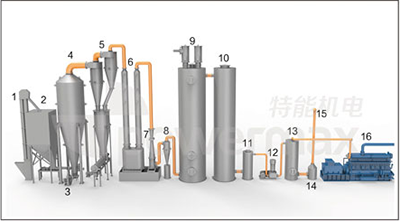

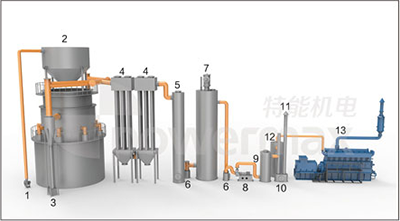

The process of Powermax

biomass gasification power generation includes three steps. The first

step is biomass gasification. Solid biomass is converted into

combustible gas. The remaining product after fixed biomass gasification

is biochar, which can be made into high-value carbon ink, barbecue

charcoal, active carbon, etc. The second step is gas purification. The

gas has impurities through gasification, including ash, charcoal, tar,

which should be removed with purification system in order to ensure the

operation of gas power generator. The byproduct after gas purification

is biomass vinegar, which can be made into foliar fertilizer, deodorant,

insecticide, etc. after concentration. The third step is gas power

generation, which use gas engines (spark plug ignition type) for

electricity generation, and the high temperature flue gas produced by

the gas engine can heat boiler to get steam or hot water for residential

or industrial use.

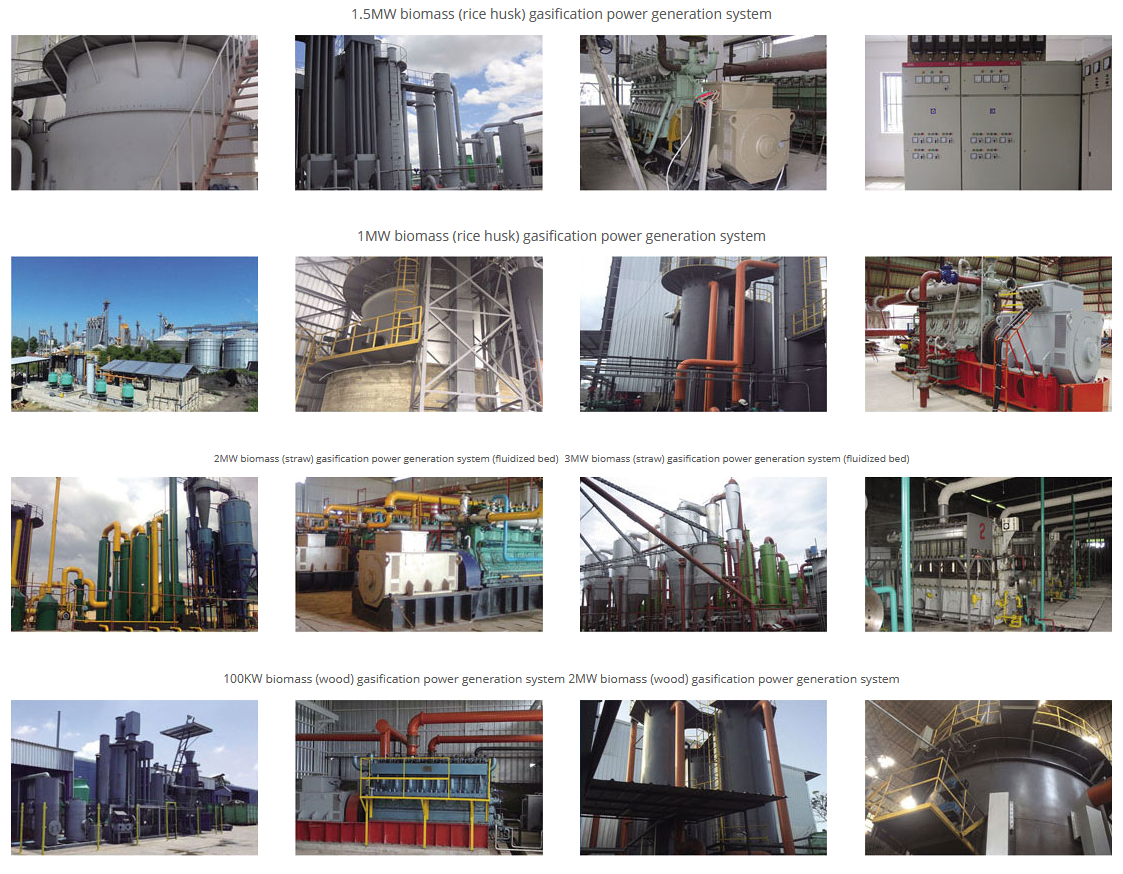

The Powermax biomass

gasification power generation system adopts modular design, which can be

normally applied to power stations of 50-20000kw. There are four models

of Powermax biomass gasification power generation systems : circulating

fluidized bed gasification system (CFGB), updraft fixed bed

gasification system (UFBG), downdraft fixed bed gasification system

(DFBG) and twin-fire fixed bed gasification system (TFBG). Each single

set ranges from 50kw-3000kw. Powermax biomass gasification power

generator sets use 500-1000rpm medium gas engine and efficient Siemens

generators, and their specifications vary from 50kw to 1200kw. Powermax

system is suitable for every kind of biomass.

Powermax Biomass

Gasification Power Generation Technology Is Different From Other

Renewable Energy Power Generation, Which Has Seven Characteristics As

Following:

1)It is a short period for

systematic supply and power plant construction. It takes 4-6 months from

contract signing to power plant operation.

2)The total investment of power plant is low.

3)The system is typical of

flexibility and simplicity. It can open and close at any time because

Powermax Biomass gasification power generation system is composed of

biomass gasifier and gas internal combustion engine(spark plug

ignition), which needs low requirement for operators and low cost for

operation and maintenance.

4)The system has better

cleanliness. The emission of harmful gas such as CO2、SO2 can be

decreased validly because the biomass belongs to renewable energy.

What’s more, the temperature of gasification process is lower(about at

700-900℃) and the accumulation of NOX is few so that the emission of NOX

can be controlled efficiently.

5)The system has higher

economical efficiency. The flexibility of biomass gasification power

generation system can ensure a higher economical efficiency of

technology in small scale. At the same time, the simple process of gas

power generation and compact equipment ensure that the investment of

biomass gasification power generation technology is lower than other

renewable energy power generation technology. In conclusion, biomass

gasification power generation technology is cost-optimal power among

all renewable energy technology.

6)Contrast with solar power

generation, wind power generation and hydraulic power generation, the

power generation time of biomass power generation system can reach

7200-8000h per year, which can get a faster return on investment.

7)The high utilization

efficiency and economic benefit of bio-production: the gaseous

production(flammable gas) is used for power generation, air supply and

instead of coal. The hot water produced in gasification process can be

used for bath and other uses, and the liquid product(wheat straw

vinegar) can be made into leaf fertilizer, deodorant and so on. The

solidoid (biochar) can be made into carbon basal fertilizer, active

carbon, barbecue charcoal and so on.

中文

中文 EN

EN

ENGLISH

ENGLISH 简体中文

简体中文