-

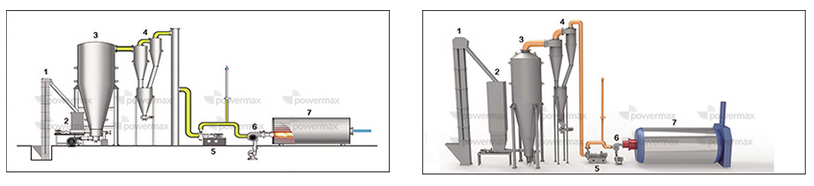

1. Elevator

-

2. Feed Bin

-

3. Gasifier

-

4.Cyclone

-

5. Booster Fan

-

6.Combustor

-

7.Gas Boiler(Dual Chamber For Selection)

Office Address:6th floor, Chuangrong Building Block C, Danshan Road, AnzhenStreet, Xishan District, Wuxi, Jiangsu, China.

Factory Address:No. 139, Jiaoyang East Road, Yangjian Town, Xishan District, Wuxi, Jiangsu, China

Skype: tnjd168

Email:info@powermaxgasifiers.com

Email:sales@powermaxgasifiers.com

Mobile/WhatsApp: +86-13812083566

Tel:+86-510-68229610

Available for steam boiler,hot-water boiler,industrial kilns,incinerator,furnace,drying equipment,food drying equipment,painting equipment,industrial annealing furnace,asphalt heating equipment,die casting machine…

1. Elevator

2. Feed Bin

3. Gasifier

4.Cyclone

5. Booster Fan

6.Combustor

7.Gas Boiler(Dual Chamber For Selection)

|

Model |

200CFBG |

400CFBG |

800CFBG |

1000CFBG |

1400CFBG |

1800CFBG |

2000CFBG |

2500CFBG |

3500CFBG |

|

Type of Gasifier |

Fluidized Fixed Bed Gasifier |

||||||||

|

Gas Agent |

Air |

||||||||

|

Moisture Requirement |

≤15% |

||||||||

|

Size Requirment |

≤10-15mm |

||||||||

|

Biomass Consumption(Kg/hr) |

200-320 |

400-640 |

800-1280 |

1000-1600 |

1400-2240 |

1800-2880 |

2000-3200 |

2500-4000 |

3500-5600 |

|

Gas Production(Nm3/h) |

500-600 |

1000-1200 |

2000-2400 |

2500-3000 |

3500-4200 |

4500-5400 |

5000-6000 |

6250-7500 |

8750-10500 |

|

Ash Discharge Type |

Dry Ash Type |

||||||||

|

Gas Temperature(℃) |

350-450 |

||||||||

|

Heat Value of Gas |

1200-1300Kcal/Nm3 |

||||||||

|

Gas Composition |

CO-12~18%, CO2-10~16%, CH4-4~8% H2-3~7% N2-54~60% O2-0.5~1.2% CmHn-1-1.4% |

||||||||

|

Adaptive Steam Boiler(t/h) |

1 |

2 |

4 |

6 |

8 |

10 |

12 |

15 |

20 |

|

Gasifier Gas Heat(10000Kcal/h) |

80 |

160 |

320 |

400 |

560 |

720 |

800 |

1000 |

1400 |

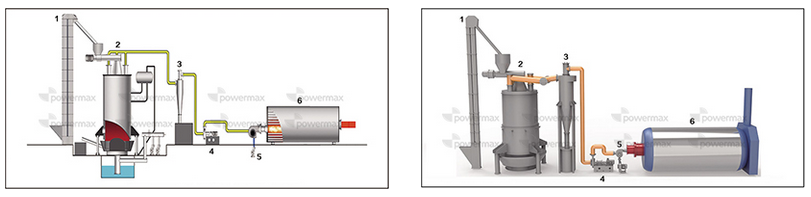

Available for steam boiler,hot-water boiler,industrial kilns,incinerator,furnace,drying equipment,food drying equipment,painting equipment,industrial annealing furnace,asphalt heating equipment,die casting machine…

1. Elevator

2. Gasifier

3. Cyclone

4. Booster Fan

5. Combustor

6. Gas Boiler(Dual Chamber For Selection)

|

Model |

200UFBG |

400UFBG |

800UFBG |

1000UFBG |

1400UFBG |

1800UFBG |

2000UFBG |

2500UFBG |

3500UFBG |

|

Type of Gasifier |

Updraft Fixed Bed Gasifier |

||||||||

|

Gas Agent |

Air+Steam |

||||||||

|

Moisture Requirement |

≤20% |

||||||||

|

Size Requirment |

Diameter 20mm-80mm;Length 10-80mm; |

||||||||

|

Biomass Consumption(Kg/hr) |

200-320 |

400-640 |

800-1280 |

1000-1600 |

1400-2240 |

1800-2880 |

2000-3200 |

2500-4000 |

3500-5600 |

|

Gas Production(Nm3/h) |

500-600 |

1000-1200 |

2000-2400 |

2500-3000 |

3500-4200 |

4500-5400 |

5000-6000 |

6250-7500 |

8750-10500 |

|

Ash Discharge Type |

Wet Ash Type |

||||||||

|

Gas Temperature(℃) |

100-200 |

||||||||

|

Type of Gas Purification |

Dry Type Gas Purification System |

||||||||

|

Heat Value of Gas |

1200-1400Kcal/Nm3 |

||||||||

|

Gas Composition |

CO-16~21%, CO2-5~11%, CH4-4~6% H2-10~12% N2-54~60% |

||||||||

|

Adaptive Steam Boiler(t/h) |

1 |

2 |

4 |

6 |

8 |

10 |

12 |

15 |

20 |

|

Gasifier Gas Heat(10000Kcal/h) |

80 |

160 |

320 |

400 |

560 |

720 |

800 |

1000 |

1400 |