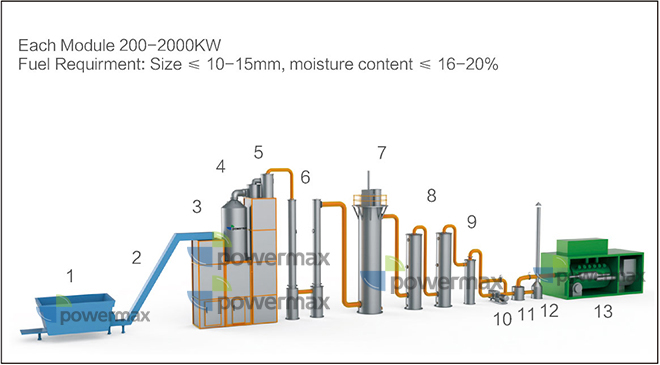

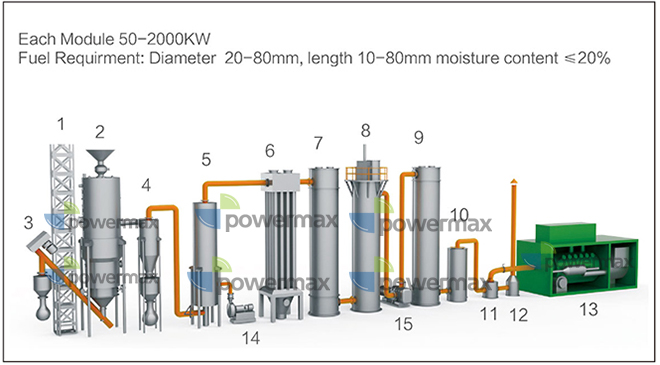

1 Biomass storage

2 Biomass Conveyor

3 Biomass Buffer Bin

4 Biomass Gasifier

5 Cyclone Dust Collector

6 Gas Filer

7 ESP

8 Gas Scrubber

9 Gas Dryer

10 Blower

11 Buffer tank

12 Gas Flare

13 Gas Generator Set

Biomass Gasification Power Generation System

The

basic principle of POWERMAX's biomass gasification power generation

system(abbreviated as BGPS) is to convert Agriculture and forestry

products and wood processing remains(including rick husks,wood

powder,branches,offcuts,corn straw,rice straws,wheat straws,cotton

straws,fruit shells,coconut shells,palm shells,bagasse,corncobs and

etc.) into comnustible gas. It is then used as fuel in gas combustion

engine to generate electricity.Biomass gasification successfully

conquers the disadvantages of biomass,such as low flammability and wide

diversity.Biomass gasification system is characteristic of small land

requirement and environment friendly. It's one of the most effective way

of biomass utilization.

POWERMAX's BGPS process includes three

steps. The First step is biomass gasification,which convert biomass into

syngas. The Second step is syngas purification.The producer gas coming

from gasifier usually contains contaminants including dust,coke,tar and

ect. The contaminants will be removed by the gas purification system to

ensure normal operation of gas engine.The Third step is power generating

in gas combustion engine(spark-plug ignition type).The hign temperature

exhuast gas may be reused by waste heat boiler to generate steam or hot

water for civil or industrial use.

The POWERMAX biomass gasification power generation systems are based on a modular concept and are able to applicable for 50-20000KW biomass power station .There are four series of biomass gasification system offered by POWERMAX which ranges from 50-2000KW of power generation:

CFBG(circulationg Fluidized Bed Gasifier) Series.

UFBG(Updraft Fixed-bed Gasifier)Series,

DFBG(Downdraft Fixed-bed Gasifier) Series,

TFBG(Twin-fire Fixed-bed Gasifier)series.

A

series biomass generator sets from 50KW to 1200KW are developed by

POWERMAX to combine with POWERMAX advanced gasification technology.These

gas generator sets are using the high efficiency Siemens technology

alternators ,Chinese top brand medium speed gas engine(500-1000rmp) with

advanced European engine controlsystems.The high performance of the

Powemax biomass gasification plants and the later production of

electricity with the gensets represents represents a competitive

solution when compared with conventional boiler-fired system.

“POWERMAX designs,projects and implements suitable solutions for each type of biomass residue.”

Comparing with other renewable power generating system,POWERMAX-BGPS is characteristic of:

1) Short project execution period.The power plant is normally started up within 4-6months after contract singing.

2) Low Investment(including equipment cost,civil work and installation cost).

3) Systems have

Flexibility and Siplicity.As the POWERMAX-BGPS mainly consists of

biomass gasifier system and gas combustion engine/generator(Spark-plug

ignition type),it is very easy to operate.System can be stared or

stopped any time,the switch time is very short. It has few requirements

for the oeprator of power plant and also requires little O&M cost.

4) Clean

technology.Biomass,as one kind of renewable energy,may reduce the

emission of carbon dioxide,sulfur dioxide causing from fossil

fuel.Nitrogen oxides emissin is very limited in our biomass gasification

power generating system because of low temperature(700℃-900℃)。

5) Economic. POWERMAX-BGPS

is capacity flexible.Even small size biomass power plant is also

profitable.Simple process and less land requirements make biomass

gasification power plant more economic comparing with other renewable

energy Generally speaking,biomass gasification power generating is the

most economic technology in renewable power generating plant.

6) Compare to Solar power

plant.Wind turbine Power plant and Hydro power plant,minimum running

hour of biomass power plant can be 7200-8000hrs per year when the

biomass fuel is enough,which makes customer to achieve a short ROI

period.

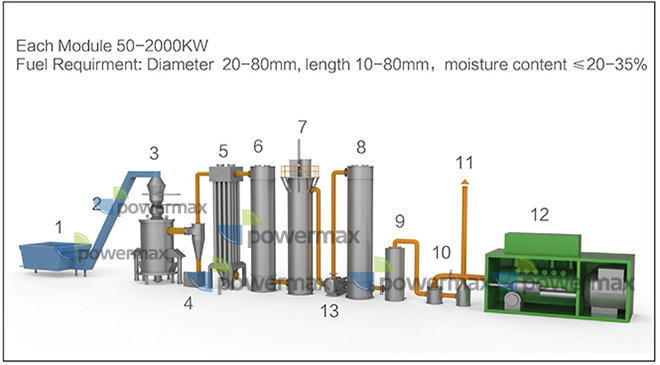

1 Biomass storage

2 Biomass Conveyor

3 Biomass Gasifier

4 Cyclone Dust Collector

5 Air Cooler

6 Gas Cooler

7 ESP

8 Gas Cooler

9 Gas Dryer

10 Buffer tank

11 Gas Flare

12 Gas Generator Set

1 Biomass storage

2 Biomass Conveyor

3 Biomass Gasifier

4 Cyclone Dust Collector

5 Air Cooler

6 Gas Cooler

7 ESP

8 Gas Cooler

9 Gas Dryer

10 Buffer tank

11 Gas Flare

12 Gas Generator Set

13 Blower

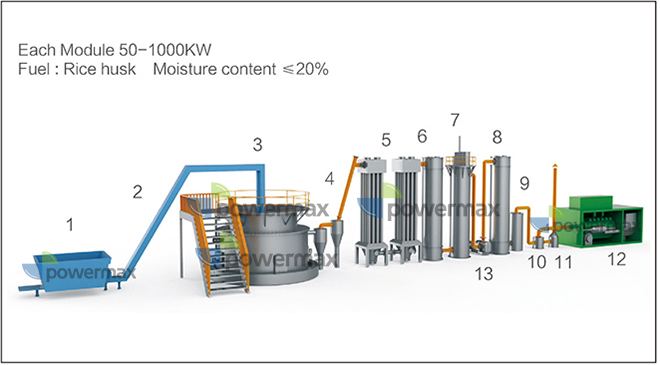

1 Skip Charger

2 Biomass Gasifier

3 Dry Ash Duscharge

4 Cyclone Dust Collector

5 Hot air Heat Exchanger

6 Air Cooler

7 Gas Cooler

8 ESP

9 Gas Cooler

10 Gas Dryer

11 Buffer tank

12 Gas Flare

13 Gas Generator Set

14 Blower

15 Gas Compressor

中文

中文 EN

EN

ENGLISH

ENGLISH 简体中文

简体中文